| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : YMP

Model Number : OEM

Place of Origin : Guangdong, China

MOQ : 100

Price : $0.545-0.559 piece

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 3000 pieces per day

Delivery Time : 7 days

Packaging Details : Inner pearl button, outside carton box, or customized

CNC Machining or Not : CNC Machining

Type : Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Machining Services

Material Capabilities : Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Micro Machining or Not : Micro Machining

Product name : OEM Manufacture 5 Axis Metal CNC Milling Parts

Material : SS

Certification : ISO 9001:2015

Finish : Clean

Description : Metal Hollow Aluminum Polished

Item : CNC Precision Machining Part

Port : Shenzhen

Drawing Format : STEP or PDF

Payment Term : PayPal or T/T

YMP is one of the leading CNC metal making manufacturer with over 18 years of experience, which was founded in 2004 and is located in Shenzhen.

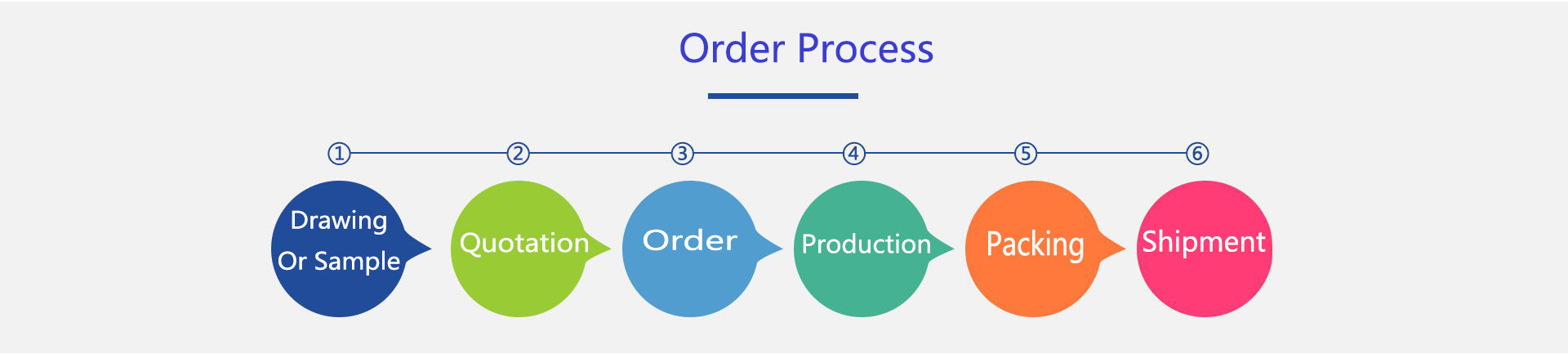

Our main businesses are customized metal and plastic parts. Such as CNC milling, CNC turning, Stamping, Plastic injection, Wire EDM cutting etc. We usually produce them according to customers' drawing or samples.

Our company also enjoyed experienced technicians and QC team who are welltrained and customer-focused to guarantee the quality of each shipment.

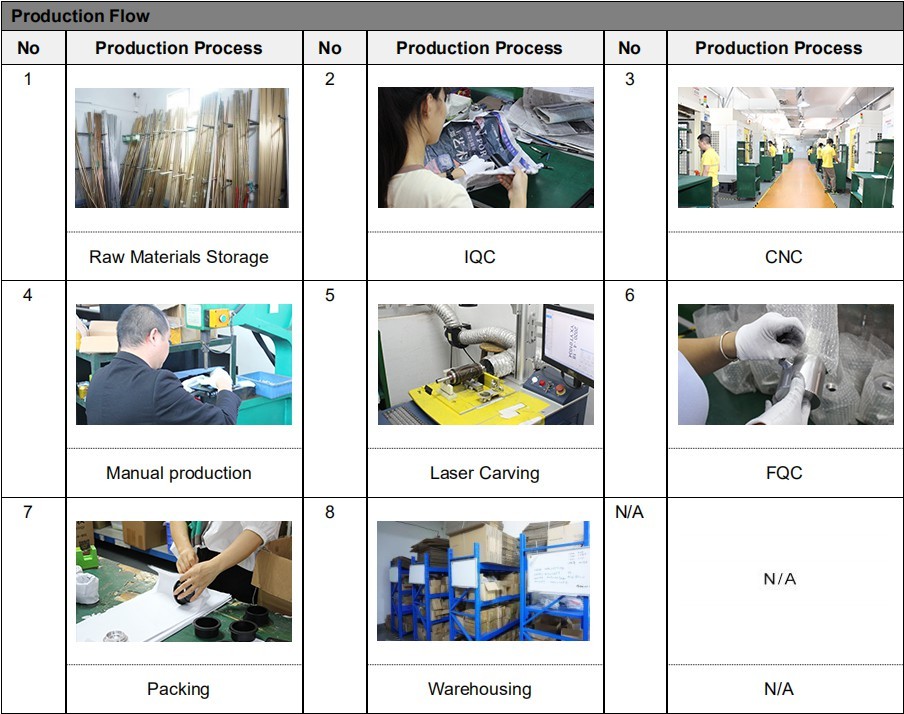

OUR FACTORY The factory covers an area of more than 7,500 square meters with advanced CNC milling machines CNC lathes, high precision wire EDM, grinding machines, etc., and inspection tools.

Introduce advanced international production lines and Strictly follow the requirements of ISO9000:2015 Quality Management System. All of our machines undergo rigorous inspection procedures to ensure the tolerances of machined parts within 0.005mm. We will keep improving to offer the best services to our customers.

| Product Name | OEM Manufacture 5 Axis Metal CNC Milling Parts | |||

| Material | 1) Metal: Stainless steel, Steel(Iron,)Brass, Copper, Aluminum 2) Plastic: POM, Nylon, ABS, PP, PEEK 3) OEM according to your request | |||

| Surface treatment | Anodized different color, Mini polishing& brushing, Electronplating(zinc plated, nickel plated, chrome plated), Power coating& PVD coating, Laser marking& Silk screen, Printing, Welding, Harden etc. | |||

| Size | According to your drawing(stp, dwg, igs, pdf), or sample, provide custom service | |||

| Factory | yes | |||

| Certificate | ISO9001:2008,SGS, ROHS, ISO9001:2015 | |||

| process | CNC machining, Auto lathing/turning, Milling, Grinding, Tapping Drilling, Bending, Casting, Laser cutting | |||

In our parts processing industry, we may all know that precision machining requires high precision. The main characteristics of precision machining are high manufacturing precision and accurate tool setting, and it can process some high-precision parts.

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.

Almost any material can be used in a CNC machine. It really depends on the application. Common materials include metals such as aluminum, brass, copper, steel, and titanium, as well as wood, foam, fiberglass, and plastics such as polypropylene, ABS, POM, PC, Nylon, etc.

When a CNC system is activated, the desired cuts are programmed into the software and dictated to corresponding tools and machinery, which carry out the dimensional tasks as specified, much like a robot.

In CNC programming, the code generator within the numerical system will often assume mechanisms are flawless, despite the possibility of errors, which is greater whenever a CNC machine is directed to cut in more than one direction simultaneously. The placement of a tool in a numerical control system is outlined by a series of inputs known as the part program.

With a numerical control machine, programs are inputted via punch cards.

By contrast, the programs for C NC machines are fed to computers through small keyboards. CNC programming is retained in a computer’s memory. The code itself is written and edited by programmers. Therefore, CNC systems offer far more expansive computational capacity. Best of all, CNC systems are by no means static, since newer prompts can be added to pre-existing programs through revised code.

Turning- Turning or Lathing involves rotating the workpiece on a machine, while a single-edged cutting tool remains stationary. The cutting tool is slowly moved parallel to the workpiece’s rotational axis, removing material as it goes.

Drilling - Drilling results in creating a round hole by rotating a cylindrical tool parallel to the workpiece’s axis of rotation. The hole created is equal in the diameter of the tool that was used.

Milling - Milling is the process of removing material, using rotary cutters, from a workpiece in a feed motion perpendicular to the rotational axis of the cutting tool. This is one of the most common forms of machining used today.

A lathe turns the material you’re machining and the tools are held stationary in the turret. Lathes are used mainly for round parts. Milling machines hold the material stationary and the tools do the movement. Milling machines are used for any shape part.

There are two main spindle orientations in CNC machining. In vertical CNC machines, the spindle axis, which is called the z-axis, is oriented vertically. In a C-column configuration, the spindle travels in this direction, and the table which holds the workpiece moves in both x and y horizontal directions. Vertical machines are perfect for projects milled from one side, such as covers and brackets.

In horizontal CNC machines, the spindle z-axis is horizontal and typically parallel to the length of the machine. The spindle travels on the vertical y-axis and horizontally on the x-axis. The pallet and fixtures hold the workpiece and move on the z-axis, and the B-axis rotates.

Horizontal machining has several advantages including accessing machining from four sides and better chip evacuation. Typically, heavy workpieces are a better fit for horizontal machines the machines are more sturdy, include pallet changers, hold more tools, and can be more easily loaded and accessed by the spindle using B-axis rotations.

Once your order is confirmed, we will execute the whole fabricate design (DFM) review, so that our engineer thinks that maybe affect any quality problems of your parts. Using a set of test equipment to check and confirm all materials. The final inspection report before shipping.

|

|

OEM SS Milled Metal Parts 5 Axis Clean Finish Anodized Different Color Images |