| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : OEM/YMP

Model Number : YMP-A025

Place of Origin : Shenzhen, China

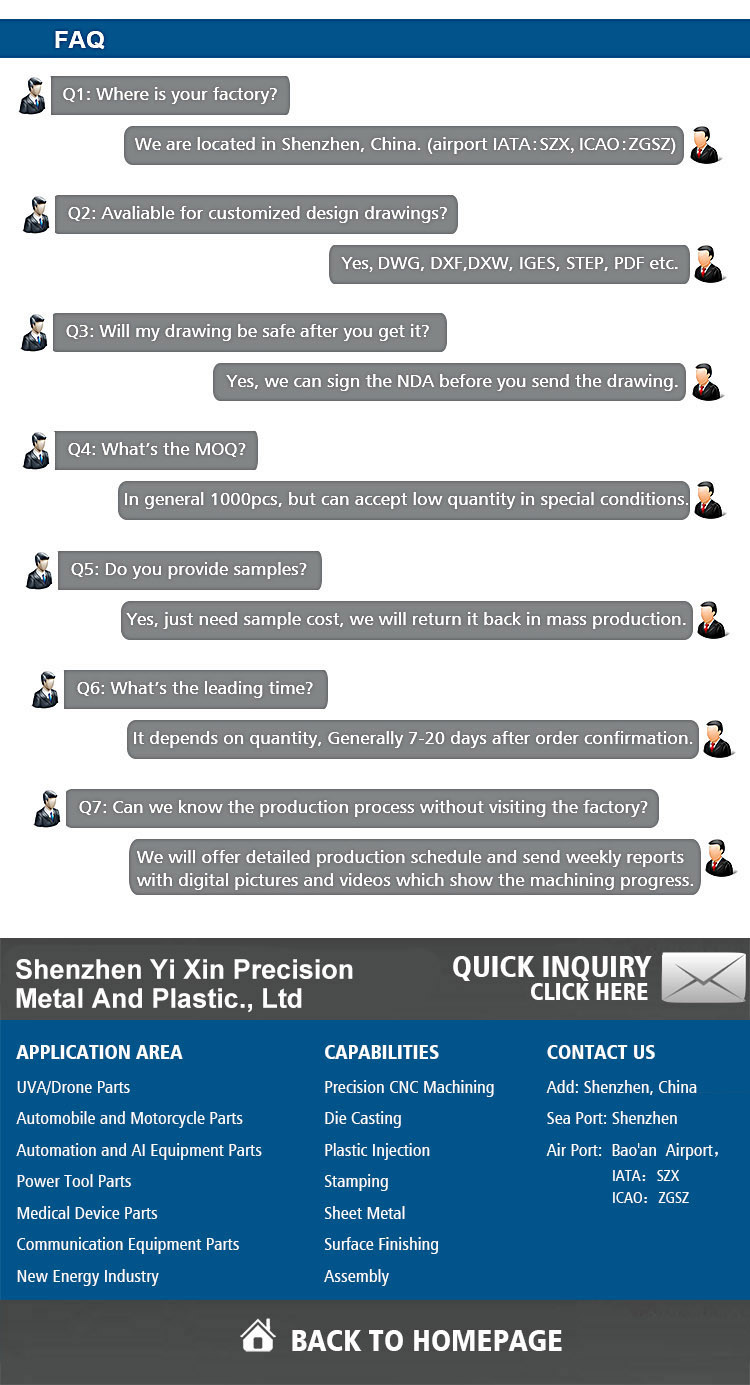

MOQ : 100

Price : $0.662-0.754 piece

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 3000 pieces per day

Delivery Time : 7 days

Packaging Details : Inner pearl button, outside carton box, or customized

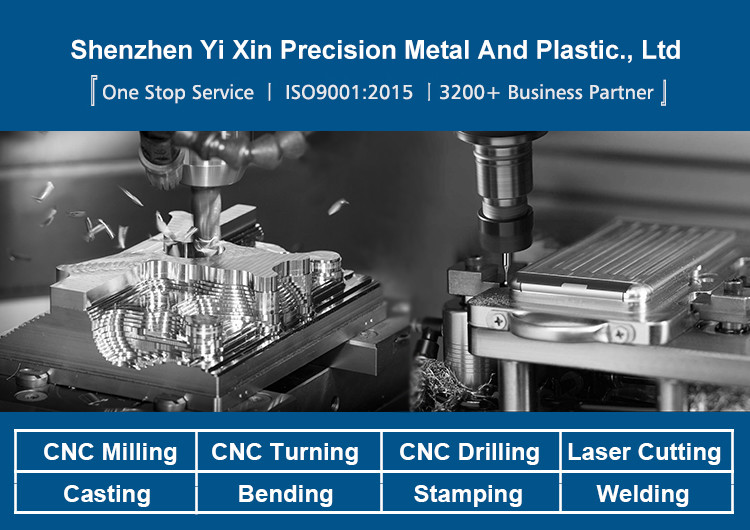

CNC Machining or Not : CNC Machining

Type : Broaching, DRILLING, Etching/Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning

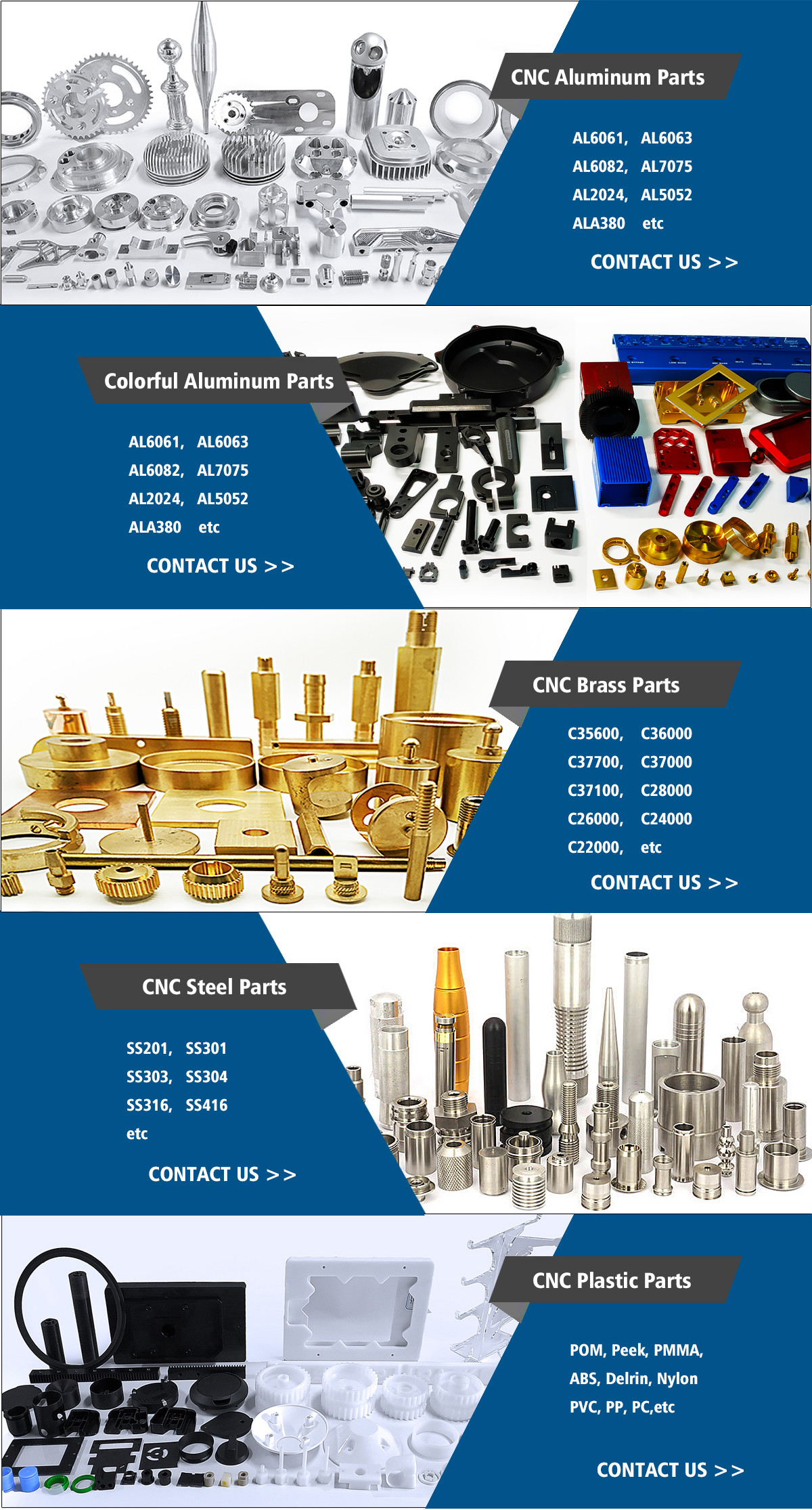

Material Capabilities : Aluminum, Brass, Bronze, Copper, Hardened Metals, Stainless Steel, Steel Alloys

Micro Machining or Not : Micro Machining

Product name : CNC Aluminum Stainless Steel Part

Material : Aluminum Alloy

Process : CNC Turning Milling

Surface treatment : Customer's Request

Service : Customized OEM

Application : Industrial Equipment

Equipment : CNC Machining Centres

Color : Customized Color

Keyword : CNC Macining Parts

Drawing Format : 2D/(PDF/CAD)3D(IGES/STEP)

| High Precision Mold | ||||

| Core/cavity material: | SKD11, D2 etc. | |||

| Material: | A3, 45# steel | |||

| Type: | press stamping, progressive press, deep drawing | |||

| Mould life: | 300,000 shoots | |||

| Size/Tolerance: | According to customer's 2d drawing | |||

| Monthly capacity: | 50000pcs | |||

| Design Software: | PROE, UG, CAD, Solidwork | |||

| Order processing procedures | ||||

| 1. Confirm drawing, order qty, surface treatment, packing, shipping and price. | ||||

| 2. Make pre-production samples. | ||||

| 3. Mass production. | ||||

| 4. Customer inspection or self-inspection as customer's requirements. | ||||

| 5. Arrange shipment. We can provide shipping assistants, customers can also arrange shipments themselves. | ||||

In our parts processing industry, we may all know that precision machining requires high precision. The main characteristics of precision machining are high manufacturing precision and accurate tool setting, and it can process some high-precision parts.

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.

|

|

OEM Custom Machining Anodizing Milling Services CNC Aluminum Parts Images |